3D printing, also known as additive manufacturing, has emerged as a revolutionary technology with the potential to transform numerous industries and aspects of our lives․ From prototyping to manufacturing, healthcare to construction, 3D printing is rapidly gaining traction, disrupting traditional processes and opening up new avenues for innovation․

The Evolution of 3D Printing

The concept of 3D printing dates back to the 1980s, with the first commercially available 3D printer introduced in 1986․ However, early iterations were limited in terms of materials, resolution, and speed․ Over the years, advancements in technology, materials science, and software have led to significant improvements, resulting in more sophisticated and affordable 3D printers․

Key Advantages of 3D Printing

3D printing offers numerous advantages over traditional manufacturing methods, making it a compelling alternative for various applications:

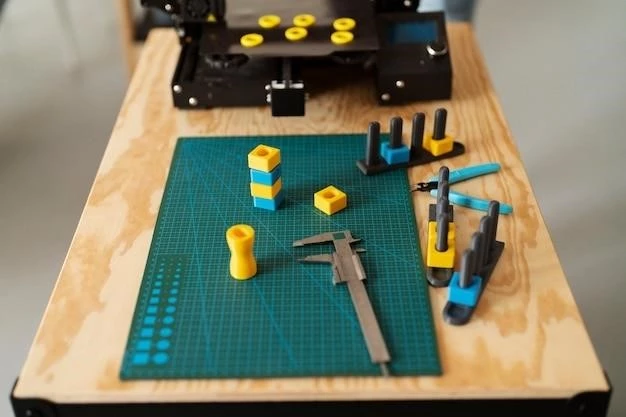

- Rapid Prototyping: 3D printing enables rapid prototyping٫ allowing designers and engineers to quickly create physical models of their designs for testing and evaluation․

- Customization and Mass Personalization: 3D printing facilitates the creation of highly customized products, tailoring them to individual needs and preferences․ This opens up possibilities for mass personalization, where products are designed and manufactured on demand․

- Reduced Waste: 3D printing is an inherently efficient process٫ as it only uses the necessary material to create the desired object٫ minimizing waste compared to traditional subtractive manufacturing methods․

- On-Demand Manufacturing: 3D printing enables on-demand manufacturing, eliminating the need for large inventories and allowing for localized production․ This reduces lead times and transportation costs․

- Complex Geometries: 3D printing allows for the creation of complex geometries and intricate designs that would be difficult or impossible to produce using traditional methods․

- Cost-Effectiveness: For low-volume production runs, 3D printing can be more cost-effective than traditional methods, especially for customized products․

Applications of 3D Printing

The applications of 3D printing are vast and continue to expand rapidly․ Here are some prominent areas where 3D printing is making a significant impact:

Manufacturing

3D printing is transforming the manufacturing industry by enabling rapid prototyping, customized production, and distributed manufacturing․ It is used to create tools, molds, fixtures, and even finished products, increasing efficiency and reducing production lead times․

Healthcare

In healthcare, 3D printing is revolutionizing patient care․ It is used to create custom implants, prosthetics, surgical guides, and models of organs for training and planning complex surgeries․ 3D-printed medical devices are also becoming increasingly common․

Construction

3D printing is gaining traction in the construction industry, allowing for the creation of complex building structures, customized homes, and infrastructure components․ It can also be used for rapid repairs and reconstruction in disaster-stricken areas․

Education

3D printing is being incorporated into educational institutions at all levels, providing students with hands-on learning experiences in STEM fields․ It promotes creativity, innovation, and problem-solving skills․

Aerospace

3D printing is playing a crucial role in the aerospace industry, enabling the creation of lightweight and complex components for aircraft and spacecraft․ It is also used for prototyping and testing new designs․

Automotive

The automotive industry is embracing 3D printing for prototyping٫ tooling٫ and the production of customized parts and accessories․ It is also used to create lightweight and fuel-efficient vehicle components․

Challenges and Future of 3D Printing

While 3D printing offers numerous benefits٫ it also faces some challenges that need to be addressed:

- Scale and Speed: Although 3D printing technology is rapidly improving, it still faces limitations in terms of speed and production scale for high-volume manufacturing․

- Material Development: The range of materials that can be used in 3D printing is still limited compared to traditional manufacturing processes․ Further research and development are needed to expand the material palette․

- Cost: While the cost of 3D printing has decreased significantly, it can still be expensive for large-scale production runs compared to traditional methods․

- Skill Gap: A skilled workforce is needed to operate and maintain 3D printing equipment and to design and manufacture 3D-printed products․

Despite these challenges, the future of 3D printing looks promising․ Continued technological advancements, expanded material options, and increased adoption across industries are expected to drive further growth and innovation․ 3D printing is poised to become a transformative force, changing the way we design, manufacture, and consume products, impacting our lives in profound ways․